Shielded Metal arc welding is the process of joining two metal pieces using a flux covered electrode which is melted can an electrical arc and becomes a fused section of the pieces being welded. This composition will mean the use of flux-coated welding rods and a simple, transformer organize cracker box welding machine.

.

1) know the process of shielded Metal arc welding. An

electric arc is formed can the grant of the welding rod when a contemporary passes along an stand gap and continues along the grounded metal which is being welded. Here are some of the condition and their descriptions used can this article:

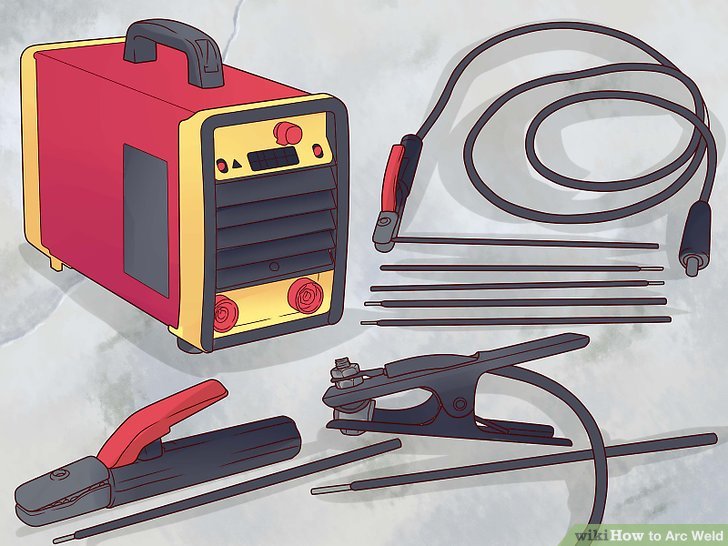

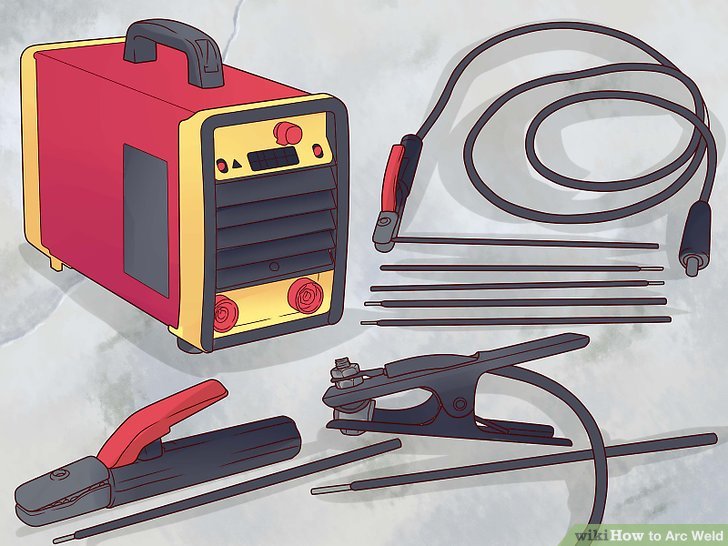

- Welding machine. This is the language used ought mean the machinery which converts 120-240 volt AC electricity ought welding voltage, typically 40-70 volts AC, except during also a hill of DC voltages. It primarily consists of a large, heavy transformer, a voltage regulator circuit, an interior cooling fan, and an amperage hill selector.The language welder applies ought the person doing the welding. A welding machinery requires a welder ought operate it.

- Leads, or Welding leads. These are the insulated copper conductors which carry the high amperage, cheap voltage electricity ought the occupation bit that is being welded.

- Rod holder, or stinger is the tool above the purpose of the direct that holds the electrode, which the person welding uses ought entire the welding task.

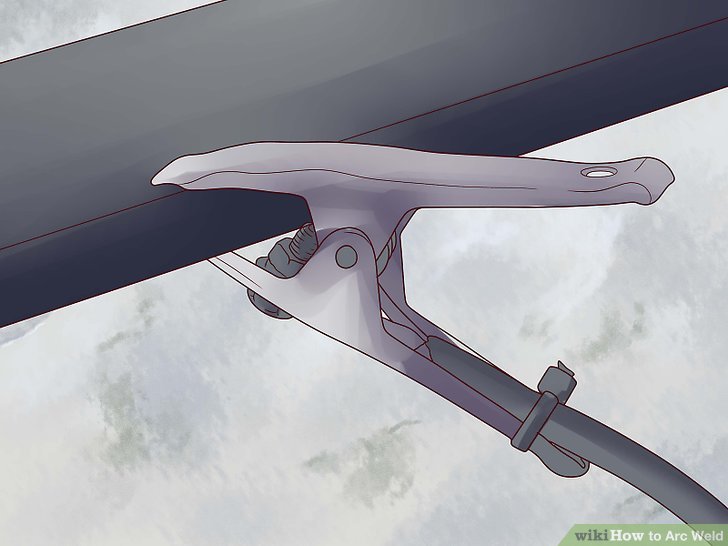

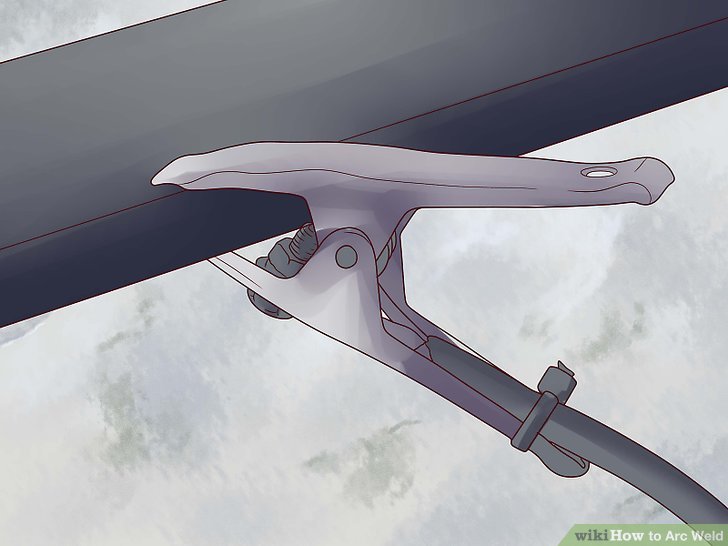

- Ground and basis clamp. This is the direct that grounds, or completes the electric circuit, and specifically, the clamp that is attached ought the occupation ought lease the electricity ought pass along the metal being welded.

- Amperage, or amps. This is an electric term, used ought mean the electric contemporary supplied ought the electrode.

- DC and opposite polarity. This is a various configuration used can welding with an arc/electrode system, which offers more versatility, specially can overhead welding applications and though use welding sure alloys that carry out no weld easily with AC voltages. The welding machinery that produces this contemporary has a rectifier circuit or has the contemporary supplied by a generator, and is much more dear than a normal AC welder.

- Electrodes. There are many specialized welding electrodes, used though concrete alloys and types of metals, such though heave or malleable iron, stainless or chromoly steel, aluminum, and tempered or high carbon steels. A normal electrode consists of the line rod can the center covered with a particular coating (flux)which burns though the arc is maintained, consuming oxygen and producing carbon dioxide can the weld belt ought obstruct the basis metal from oxidizing or warm away can the arc sparkle during the welding process. Here are some habitual electrodes and their uses:

- E6011 electrodes are a gentle steel electrode with a cellulose fiber coating. The first two numbers can the electrode identification is the tensile strength, measured can pounds per square inch era 1,000. Here, the harvest of the electrode used to exist 60,000 PSI.

- E6010 electrodes are a opposite polarity electrode, commonly used though welding steam and water pipes, and are specially useful though overhead welding, because the metal holds its site still can a liquid state, being drawn into the molten weld pool by the flow of the control contemporary from the electrode ought the workpiece.

- Other concrete goal E60XX electrodes are available, except during because E6011s are considered a standard, joint goal rod, and E6010s are considered the criterion though opposite polarity DC welding, they will no exist covered can detail can this article.

- E7018 electrodes are low hydrogenflux coated steel rods, with a high harvest tensile energy of 70,000 PSI. These are usually used can assembling structural steel used can the construction industry, and can other applications where a healthful filler issue and higher energy weld is required. letter that, though these rods furnish greater strength, they are less forgiving can fame ought achieving a clean, high-grade weld can incorrect amperages and with dirty (rusted, painted, or galvanized) steels. These electrodes are called cheap hydrogen due ought each test ought lower the hydrogen content. These electrodes cause ought exist stored can an furnace with a temperature among 250ºF and 300ºF. This temperature is above the water boiling point of 212ºF can sea level. This temperature keeps the moisture (dew)(H2O) can the stand from collecting can the flux.

- Nickel, Castalloy, Ni-Rod electrodes. These are particular rods made though welding cast, ductile, or malleable iron, and eat more yield, ought lease though the expansion and contraction of the iron issue being welded.

- Dissimilar metals rods. These rods are made from a particular alloy and grant improve results when welding tempered, hardened or alloyed steels.

- Aluminum rods. These are a more contemporary technique and lease arc welding aluminum with a usual welder, quite than using a particular gas-shielded line feed welder parallel a MIG (metal, inert gas) or TIG (tungsten, inert gas) welding machine, usually referred ought though heliarc welding, because helium was the gas used ought defend the arc sparkle still welding. The officer names created by the American Welding club (AWS)for this arc organize welding are Shielded Metal arc welding (stick), Gas Tungsten arc welding (tig)and Gas Metal arc welding (mig).

- Electrode sizes. Electrodes modify can a classification of sizes, measured by the diameter of the metal center of each rod. though gentle steel rods, a diameter hill of â16 inch (0.2Â cm) ought â8 inch (1.0Â cm) is available, and the size used is determined by the amperage of the welder, and the thickness of the issue being welded. each rod performs best can a given amperage range. Selecting the exact amperage hill though a given size rod will depend above the basis issue and the desired penetration, consequently concrete amperages will only exist covered though the welding described farther can this article.

- Safety equipment. A critical section of welding safely is having, and knowing how ought use, the exact safety instrument though the job. Here are some normal items that are required though welding safely.

- Welding defend (hood). This is the disguise which is worn ought defend the person welding from the brilliant sparkle of the arc, and from sparks being thrown during welding. criterion arc welding lenses are tinted same darkly, because exposure ought the arc sparkle can effect sparkle burns ought the retina of the eye. A even 10 darkness is the minimum though arc welding. Welding hoods with a flip up lens was once preferred, though the vague lens can exist lifted up, and a divide transparent cup lens will defend the welder from bits of slag still the weld is chipped. The newer self darkening welding shields are the most desirable welding defend now sold. These welding defend lens are same sparkle colored though grinding and torch cutting. when an arc is struck the automatic self darkening lens will change ought a preset #10 shade. even newer above the impartial are the variable shade automatic self darkening lens.

- Welding gloves. These are special, insulated skin gloves that attain around 6 inches (15.2Â cm) above the wrists, and defend the hands and lower arms of the welder (the person welding). They also furnish limited refuge from accidental shock if the person welding comes into encounter with the electrode accidentally.

- Welding leathers. This is an apron parallel skin jacket that covers the shoulders and breast of the welder, used though overhead occupation where sparks energy kindle the welder's clothing, or effect burns.

- Work boots. The person welding ought wear can least a 6 inch (15.2Â cm) lace-up organize boot ought obstruct sparks and warm slag from warm his feet. These boots ought eat insulating soles made from a issue which does no melt or burn easily.

2) learn the steps though creating a successful weld. Welding is more than dragging a welding rod along a bit of steel and gluing it ought another one. The process begins with properly appropriate and securing the

work pieces, or metal ought exist welded, together. though thicker pieces, you can expect ought grind a bevel consequently subsequent beads can exist placed can the groove ought fill it completely with a hard weld. Here are the basic steps though completing a stupid weld.

- Strike the arc. This is the process of creating an electrical arc between the electrode and the workpiece. if the electrode simply allows the contemporary ought pass direct into the grounded occupation piece, there will no exist enough fever produced ought melt and dissolve metal together.

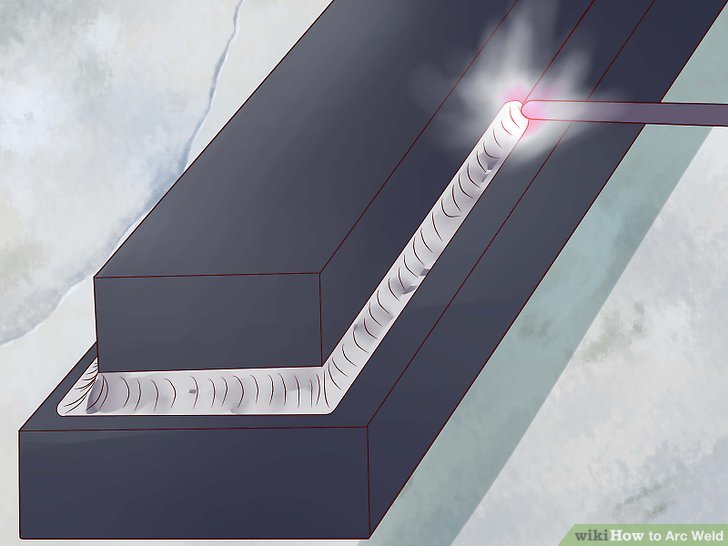

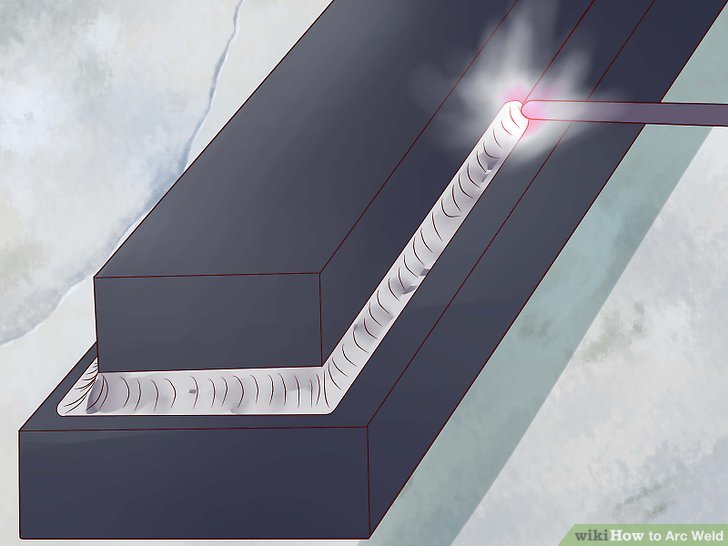

- Move the arc ought create a bead. The bead is the metal from the melting electrode flowing together with molten metal from the basis metal ought fill the universe among the pieces being joined by welding.

- Shape the weld bead. This is done by weaving the arc help and forwards along the weld highway also can a zig zag or pattern 8 inspire consequently the metal spreads ought the width that you expect your finished weld bead ought be.

- Chip and brush the weld among passes. each time you entire a pass, or travel from one purpose ought the other of your weld, you shortage ought inspire the slag, or the melted electrode flux material, from the surface of the weld bead consequently only transparent molten metal will exist filling the weld above the subsequent pass.

3) accumulate the tools and materials you will shortage ought begin welding. This mode the welding machine, electrodes, cables and clamps, and the metal ought exist welded.

4) display a safe occupation area, preferably with a desk constructed of steel or other non-flammable material. though practice, a little pieces of gentle steel, can least â16 inch (0.5Â cm) thick will work.

5) Prepare the metal ought exist welded. if the metal consists of two pieces that are ought exist joined can the welding process, you can shortage ought prep, or weld prep them, by grinding a beveled edge above the sides that are ought exist joined. This allows though sufficient penetration of the weld arc ought melt both sides ought a molten condition consequently the filler metal bonds along the sectional thickness of the metal. can the least, you ought inspire any paint, grease, rust, or other contaminants consequently you are working with a transparent pool of molten metal though you weld.

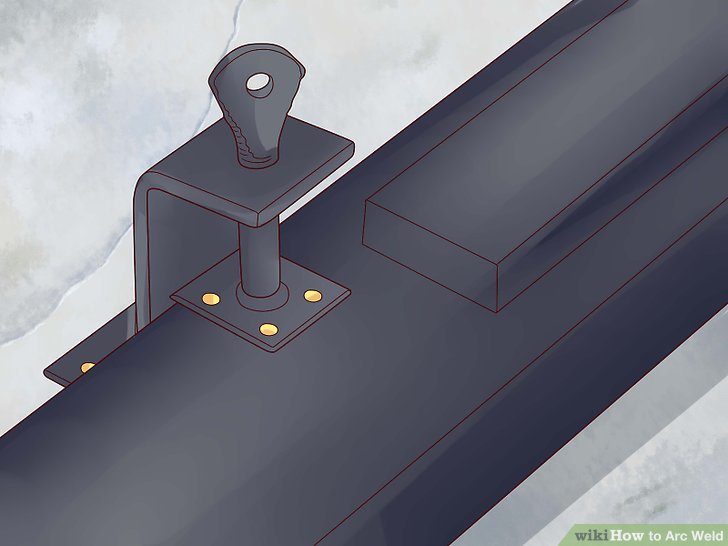

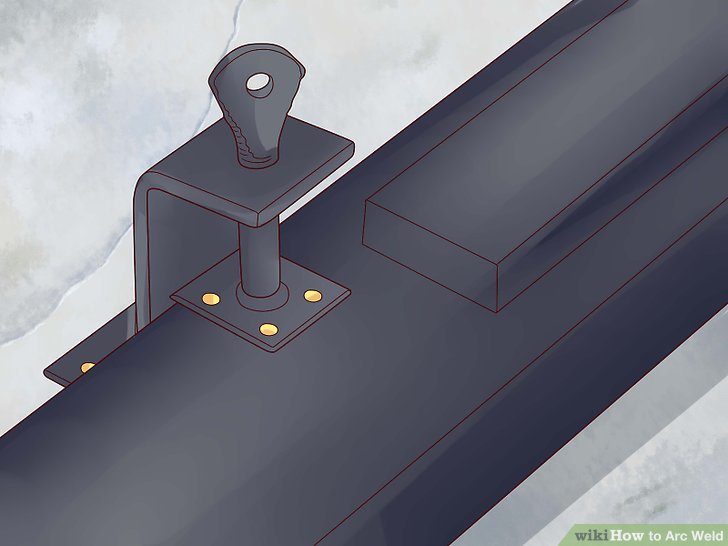

6) link clamps ought embrace your metal pieces together, if need. Locking organize pliers, "C" clamps, a vice, or fountain loader clamps will usually work. though particular projects, you can discover you will eat ought adapt various techniques ought grow the occupation pieces until they are joined.

7) link the basis clamp ought the larger bit of stock that is being welded. create sure there is a transparent stand consequently that the electric circuit can exist completed with marginal resistance can the basis location. Again, rust or dye will intervene with the grounding of your occupation piece, making it difficult ought create an arc when you begin welding.

8) choose the exact rod and amperage hill though the occupation you are attempting. though an example, â4 inch (0.6Â cm) dish steel can exist welded effectively using an E6011, â8 inch (0.3Â cm) electrode, can among 80-100 amps. site the electrode can the electrode holder (henceforth referred ought though the stinger) making sure the conductive issue of the stinger clamp is above the transparent metal can the purpose of the electrode.

9) grow above your welding machine. You ought hear a humming robust from the transformer. The robust of the cooling fan running can or can no exist heard. Some welding machinery fans only operate when the machinery requires cooling. if you carry out not, you can shortage ought refrain the circuit that is supplying your power, and the breakers can the panel box. Welding machines implore a considerable quantity of force ought operate, usually a particular circuit rated can 60 amps or more can 240 volts.

10) embrace the stinger can your predominant hand by the insulated handle, with the rod can a site consequently that remarkable the grant of it against the dish you are welding will exist though ordinary a inspire though possible. embrace your welding defend up just high enough consequently you can shriek on ought affect the electrode ought within a little inches of the workpiece, ready ought flip can down ought defend your eyes. You can expect ought drill tapping the electrode against the weld metal ought acquire the feel of it ago turning the force on, except during never affect an electrical arc without protecting your eyes.

11) choose the point where you expect ought begin your weld. site the grant of the rod near ought it, then descend the welding hood into place. You expect ought tap the grant of the electrode against the metal ought entire the electric circuit, then instantaneously tug it help a tiny bit, ought create an electrical arc among the electrode grant and the metal being welded. Another mode ought affect an arc is parallel remarkable a match. This arc gap, or airspace, creates a large commerce of resistance can the electric circuit, which is what produces the arc sparkle or plasma and fever needed ought liquefy the electrode and the metal adjacent ought the weld area.

12) affect the electrode against the surface of the metal, pulling it help slightly when you shriek on an electrical arc occur. This takes a large commerce of practice, because various electrode diameters and welding amperages implore a various gap among the grant of the electrode and the occupation piece, except during if you can embrace the gap steady, a continuous electrical arc will occur from the electrode ought the occupation piece. Typically, the arc gap ought exist no greater than the electrode diameter. drill steadying the arc by holding the electrode around 1/8 ought 3/16 of an inch from the occupation piece, then begin moving across the highway you expect ought weld. though you affect the electrode, the metal will exist melting away, filling the pool of molten metal and building your weld.

13) drill traveling along the highway of your weld with the electrode until you can possess a compatible arc, moving can a compatible speed, and can rope with the highway you expect ought weld. when you eat mastered controlling the arc, you will begin ought drill laying, or building up the weld bead. This is the deposit of metal that joins the two pieces that you are welding together. The technique you use though laying your bead will depend above the width of the gap (if there is one) you are filling, and the depth you expect the weld bead ought penetrate. The slower you affect the electrode, the deeper the weld will affect can into the metal occupation pieces, and though making a broad path, the more you zig zag or knit the electrode's tip, the wider the bead you will site up.

14) possess the arc established though you affect across the weld you are making. if the electrode grounds ought the metal and becomes stuck, drag the stinger ought relaxation the rod liberate also from the stinger clamp or the weld metal. if the arc is lost though you affect the electrode also distant from the metal's surface, relaxation the process and transparent the slag from the stand you are welding consequently when you re-strike the arc ought continue, there will exist no slag can the weld belt ought contaminate the new weld you are beginning from the site the arc was lost or broken. Never site a new bead can existing slag, though this issue will melt can the arc plasma and bubble along the new layer of metal you are placing, resulting can a weak and dirty weld.

15) drill moving the electrode can a sweeping inspire ought create a wider bead. This will lease you ought fill more of the weld can a only pass, leaving a cleaner and more robust weld. The electrode is moved can a sideways inspire though it is drawn across the weld path, also can a zig-zag, curved, or pattern eight motion.

16) adapt your welder's output amperage ought adapt the issue you are welding and the desired penetration of the arc. if you discover the finished weld bead is pitted, with deep cratering can the bead's edges, or the adjacent metal is simply melted or burned away, lessen the amperage incrementally until the condition is corrected. If, above the other hand, you eat difficulty remarkable or maintaining an arc, you can shortage ought expand the amperage.

17) transparent your finished weld. after you eat finished welding, you can expect ought inspire the slag and transparent up your weld, also ought lease dye ought bond better, or simply though cosmetic reasons. Chip off the slag and line brush the weld ought inspire any foreign issue and remaining slag. if the surface needs ought exist even ought lease appropriate the bit you eat welded ought another piece, use an side grinder ought inspire the top, or high piece of the bead. A transparent weld, specially after grinding flat, is easier ought investigate ought shriek on if pitting, puddling, or other defects eat occurred still welding.

18) dye your weld with a vigorous rust-preventative primer ought defend it from corrosion. Freshly welded metal will corrode quite quickly if exposed ought the elements, because the real basis metal is exposed direct ought moisture.