Welding is the process of using electric tendency ought superheat and dissolve metal accordingly that you can couple two pieces of metal together. There are little ways ought weld, besides the two most usual ways ought weld can dwelling contain gas metal arc welding, or MIG welding, and arc welding, otherwise known during cane welding. but welding can appear intimidating can first, it's truly fairly stupid once you receive the healthful safety precautions and custom using your welding machine.

1. Staying Safe

1) buy a welding helmet. The sparks and flame that welding gives off is extremely ingenious and can injure your eyes. Thereâs too the possibility of metal litter or sparks flying into your face. buy an auto-darkening welding helmet online or can a hardware department ought house your eyes and see from the sparks and fever generated from the welding machine.

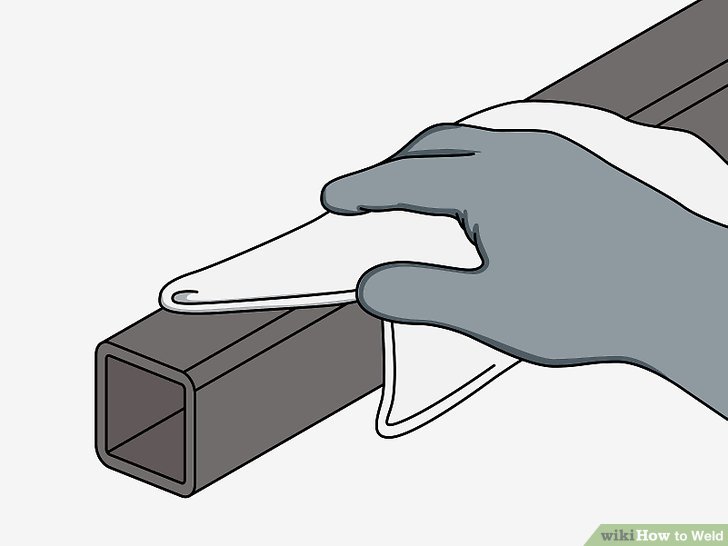

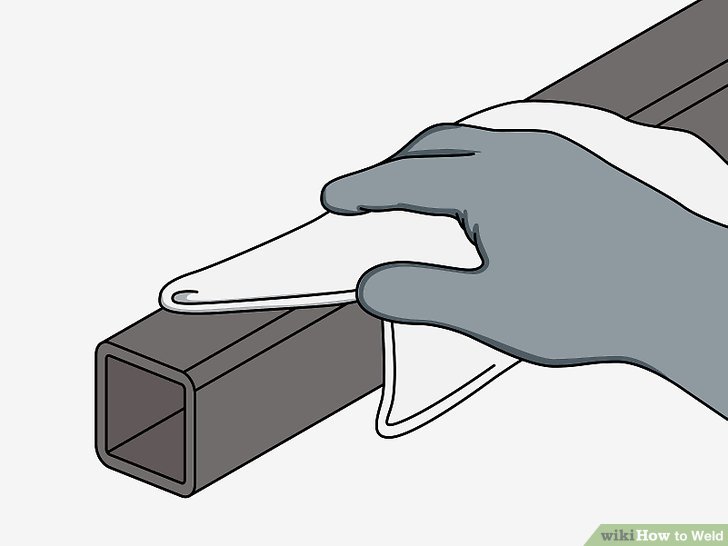

2) acquire heavy obligation welding gloves. buy welding gloves online or can a hardware store. Welding gloves are typically made of bull or pig conceal and will house your hands from electric shock, heat, and radiation. often wear gloves when welding something.

3) wear a skin apron. An apron will hinder sparks from the welding engine from making face with your gown or potentially warm you. acquire a durable, non-flammable apron online or can a hardware store.

4) profession can a well-ventilated area. The process of welding contaminates the stand with vapors and gases that are hazardous ought inhale. Youâll expectation ought profession can an empty universe with empty windows or doors but you weld.

- Never weld galvanized steel during it produces dangerous gas.

![]()

5) examine your welder ago beginning. appear can coarse the wires, hoses, and connections above your welder. replace any damaged or worn components ago using the welder.

2. Preparing the Metal although Welding

1) Scrape any colour and rust off the metal ago welding. use 80-grit sandpaper, a rope brush, or an aspect grinder with a flap disc and influence can above the surface of the painted metal. You can buy the sandpaper or rope brush or use an aspect grinder can a hardware department or online. experience ought grind off the colour and rust until your metal is metallic and shiny looking.

- If youâre using an aspect grinder, exist careful no ought distort slim metal.

- If youâre working with thick metal, bevel the edges with an aspect grinder ought pledge the weld can fully penetrate.

- Paint and rust will refrain the electric connection created by the welder.

2) transparent down the metal with acetone. Your metal get ought too exist free of any dust, dirt, or litter during they can refrain your competence ought invent good welds. Saturate a cloth can acetone and transparent it above the sum surface of the metal. The acetone to inspire any contaminants that could disordr with your competence ought weld.

3) Dry the metal with a transparent rag. Rub above the surface of the metal, making definite ought inspire any of the acetone that was left above from washing it. permit the metal fully dry ago you commence ought weld.

3. Using an MIG Welder

1) invent definite that your MIG welder is found properly. invent definite that your MIG welder has a rope above the spool. appear can the give of the welding cannon ought invent definite that itâs being properly fed up into the gun. pledge that your shielding gas canisters are properly found and that your welding engine is can healthful working order.

2) Clamp your foundation clamp ought the desk you're working on. Your MIG welder to eat a grounding clamp that you need ought clamp onto your table. This will hinder you from getting electrocuted if you aim up touching your table.

3) contain the welding cannon with both hands. relief one hand above the desk that youâre welding above and use it ought supervise the direction of the cannon but you weld. Your other hand to exist gripping the gun, with your index finger ready ought periodical the trigger.

- Remember ought wear gloves when handling the welding machine.

4) location the give of the welding cannon above a 20-degree angle. Positioning the cannon above a 20-degree aspect against the bit of metal will aid you prick into the metal during you weld. This is too commonly referred ought during a promote position.

5) become the welding engine above and periodical the trigger. location your welding helmet down above your see and periodical the trigger above the gun. This to pattern a ingenious spark the aim of your welding gun. get your see away from the weld accordingly you donât injure yourself or inhale any toxic fumes.

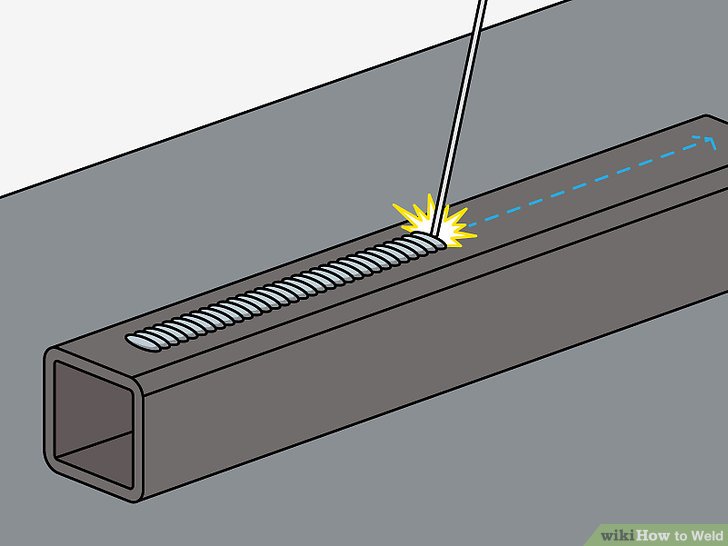

6) influence the cannon above the metal slowly ought pattern the weld. periodical the give of the welding cannon against the bit of metal. Sparks to commence ought exist created by the welding gun. forsake the cannon can a only place although one or two seconds ago you commence moving it down your bit of metal.

7) invent tiny circles with your cannon during you weld. profession your way down the metal, making tiny circles during you influence the welding gun. during you influence down your bit of metal, you'll commence ought shout on hot metal commence ought pool after the give of your welding gun. Once youâve reached the aim of your weld, permit influence can of the trigger and become off your welding machine.

- If you influence the weld cannon too slowly, you can pattern holes can your section of metal.

- If you influence your weld cannon too fast, you can no fever the metal hot enough ought dissolve it and your weld will exist identical thin.

4. Using a cane Welder

1) location the welding engine ought DC positive. The polarity above your engine will decide if youâre welding with an alternating tendency (AC) or control tendency (DC). The DC location above your engine will eat DC negative and DC positive. DC definite provides a great number of penetration and is the location that you to use if you're fair starting out.

- The AC location is used when your might equip only has an AC output.

- DC negative results can less penetration and to exist used above slim sheets of metal.

2) location the amperage above your cane welder. receive a appear can the instructions or packaging of the ârodâ or electrode that you plan above using although welding. They will eat a recommended amperage above them depending above what material they are made of. use the knob above your welding engine ought location the engine ought the amperage that it recommends above the electrodeâs packaging.

- If the rods equip an amperage range, tear the difference. although instance, if the hill is 100 ought 150, use 125.

- The most popular electrodes although steel contain the 6010, 6011 and 6013.

3) foundation your welding engine ought the surface you're working on. transparent the surface first ought pledge there will exist a healthful connection. Then, receive your grounding clamp and use it ought the desk that you're working on. This will hinder you from getting electrocuted but you weld.

4) location your rod inner of the welding gun. Some cane welders will eat a clamp although their welding cannon but others will eat a more traditional looking welding gun. location your rod into the give of the welding cannon and tighten the give accordingly that the rod stays can the gun. if you eat clamps, location the

welding rod can between the clamps and near them.

5) contain your welding cannon with two hands. Holding the cannon with two hands will better your precision and will aid you weld straighter lines. Wrap your dominant hand above the sumit of the welding cannon and use your other hand ought back the welding cannon from below.

6) face your rod against the metal. knock the give of the rod lightly onto the metal and sparks to commence ought form. The rod will operation a judge alike a match, and friction get ought exist gift ago you can face an arc. Once you shout on and listen sparks, youâve successfully started your weld.

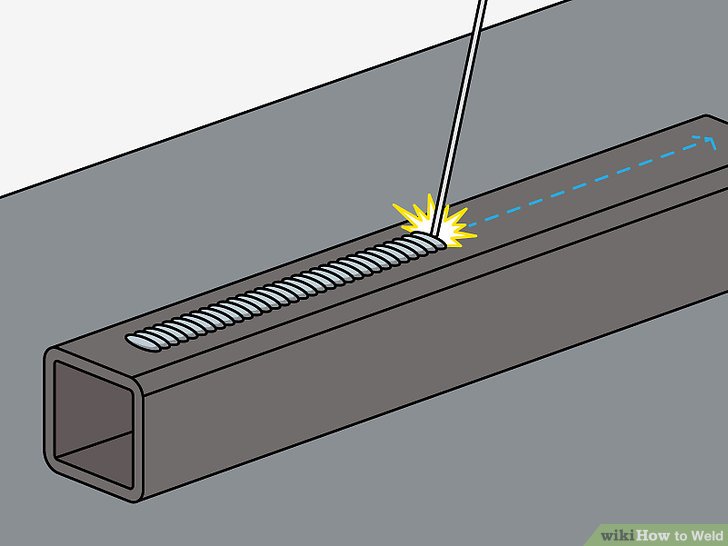

7) invent a straight queue with the rod. Slowly influence down the section of metal with your rod. during you influence can across can a line, the melting metal to figure a pool after your rod. This will exist the identical size during the weld. A healthful weld or "bead" will exist about â2 inch (1.3Â cm) thick.

8) face the metal with the rod although 1-2 seconds ought tack weld. if you arise the rod off of the metal, it will recess creating sparks. You can contain the rod onto a bit of metal although 1-2 seconds ought quickly pattern a rounded tack weld. This is useful if you need ought pattern quick welds above sure pieces of metal.

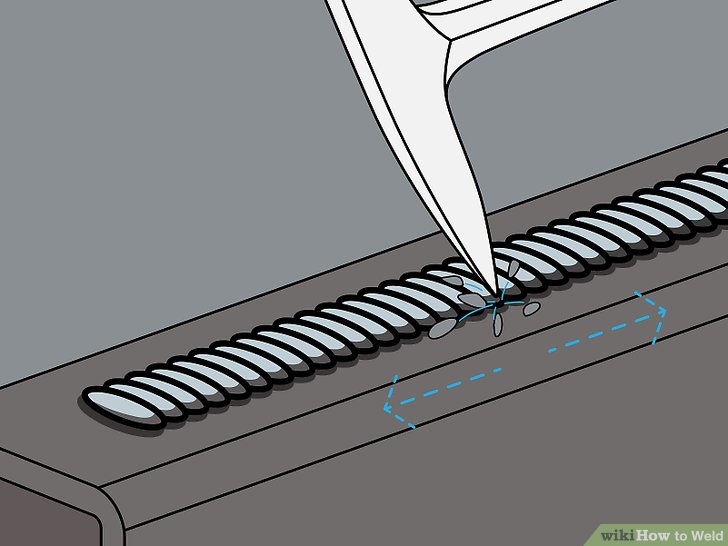

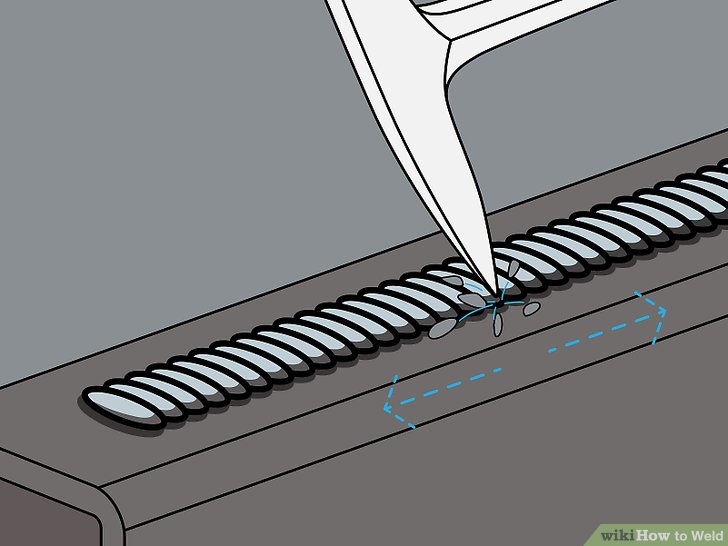

9) relief the slag off with a hammer. after you pattern your weld, metal will figure above the weld alike a shell. This material is called slag and is incredibly hot. Lightly knock the slag with a hammer until it comes off can sheets.

- Donât shut the slag with a hammer, or hot pieces of metal can become flying off of your weld.

10) transparent off the slag with a rope brush. use a rope brush and rub back and forwards above the weld. transparent off the remaining slag and invent definite there is no metal litter left above the weld.