Now that you eat yourself a Buzz Box, you are possibly eager ought visit what this tiny arc weld er can do. Your first attempt at welding can appearance similar you wasted a fate of time and money acquiring a slice of crap that clearly doesn't work. cease assured, you eat a welding machine that is able of producing feature welds with the precise welding electrodes and a tiny assist from you.

.

1) ago we start, let's acquire an parliament of what happens when we motion an arc with welding electrodes. The size of the welding rod, amperage and dish thickness determine weld fusion (adhesion) initially. at other words, a big diameter welding rod above a slim steel dish will blow precise across it. above the flip side, a few diameter welding rod above thick steel dish can no commence the arc and, if you do, the weld will no dissolve ought the steel besides simply put above the surface of the steel plate. This is where preheat comes ought your aide. Preheat allows you ought employ few welding electrodes with your buzz box above thick steel plate.

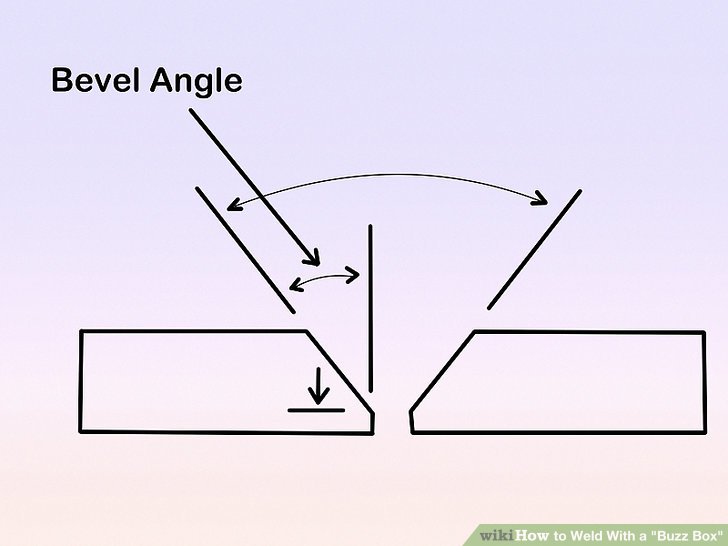

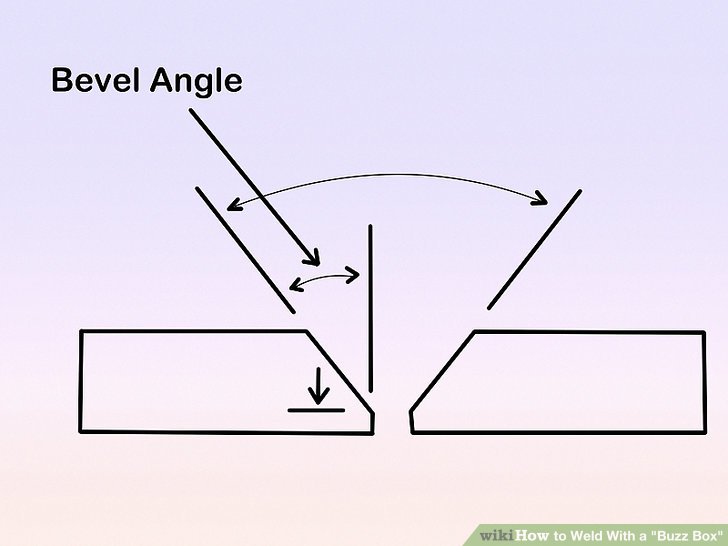

2) Prepare The Bevels and Lands

- Prepare ought wipe the steel plates by donning your safety equipment, welding helmet, welding gloves and a dirt mask though particles. "Junk In, litter Out", is exactly what you will acquire if you perform no prepare the steel plates though welding. Never weld across trash, rust or scale if you eat the fashion ought wipe the steel. The bevel ought approximate 45 degrees with a 1/8" dirt (flat) at its base.

3) put The Root Gap

- When the bevel has been applied ought both steel plates, grow them appearance down, put the root gap (I employ the metal stub of the welding electrode I'm welding with) and hire location welding ought tack them into position.

4) location The Steel Plates

- Now that the plates eat been cleaned, beveled and tacked, clamp the steel dish at a location of console and prepare ought weld the root pass. deduce your welding supplies, gas and torch though preheating, welding electrodes, stinger and your Buzz Box.

5) Preheat The Steel Plates

- It is never a bad sentiment ought preheat, at fact, about each welding profession I carry out professionally demands a preheat temp of 400 degrees and up. You will exist amazed at how easily the arc strikes and how robust the welding rod burns, improving welding feature significantly. endure at mind, once the steel has reached preheat temp, this temp get ought exist maintained throughout the procedure till total welding is finished.

6) flow The Root Pass

- Extra brood ought exist taken when running the root pass though if the root pass has good fusion and is watertight, the cease of the welding is impartial formality specially when welding pipe. compose sure the common is good and warm and you are comfortable during the weld. console fashion control.

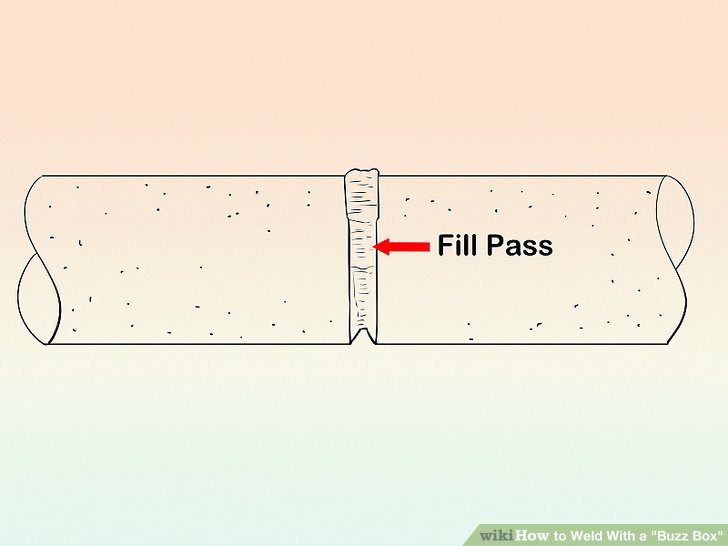

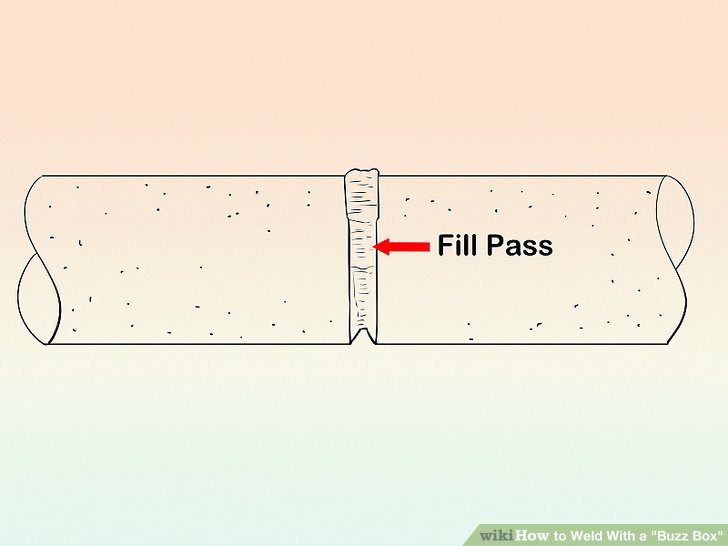

7) flow The Fill Passes

- Run the welds at steps starting with the root pass, the intermediate fill pass and the persist fill. though you step up the welds, revenue particular attention ought tying at the sides, this is the might of your welding.

- The "Cap" passes are where you allow your skills shine. They can exist though little though one or though many though it will accept ought cover the filled common you impartial welded. This is your signature therefore accept your time and acquire them straight and the likely height. The big finale' of this episode is ought grow the dish over, grind out the root opening down ought flawless metal, preheat the steel plate, fill the common and flow the caps, you're done.